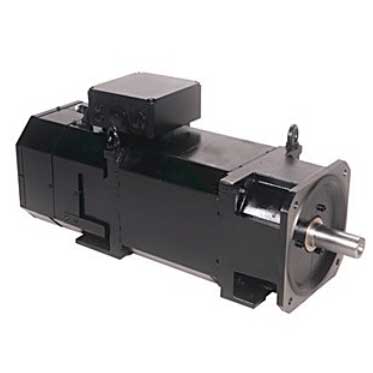

To get the power your application requires, you may be sacrificing the tight control and high performance required for increased throughput. Finding a servo solution which combines high power with precise positioning capability would provide significant advantages. Now, Rockwell Automation can help you achieve those competitive advantages with the Allen-Bradley HPK-Series High Power Induction Servo Motors. Unlike typical induction motors, the HPK-Series Servo Motors feature windings that are optimized for servo control coupled with high resolution feedback to provide the precision your application requires. These high horsepower motors employ proven induction motor technology providing high reliability and durability in demanding applications. These AC motors were specifically engineered for optimized performance when used with the Allen-Bradley Kinetix 7000 High Power Servo Drive. When you team HPK-Series Motors with Kinetix 7000 drives, you’re getting products that have been performance tested as a system. The motor and drive are designed to work together to provide a superior solution and extend the range of Kinetix Integrated Motion solutions up to 150 kW.

| Mfr. Part No. | Description |

| HPK-B1307C | Peak Stall Current Amperes (0-peak) 80.0 |

| HPK-B1308C | Peak Stall Current Amperes (0-peak) 119.3 |

| HPK-B1310C | Peak Stall Current Amperes (0-peak) 144.0 |

| HPK-B1613C | Peak Stall Current Amperes (0-peak) 217.0 |

| HPK-B1815C | Peak Stall Current Amperes (0-peak) 402.0 |

| HPK-B2010C | Peak Stall Current Amperes (0-peak)440.0 |

| HPK-B2510C | Peak Stall Current Amperes (0-peak) 826.0 |

| HPK-B1307E | Peak Stall Current Amperes (0-peak) 146.6 |

| HPK-B1308E | Peak Stall Current Amperes (0-peak) 190.3 |

| HPK-B1609E | Peak Stall Current Amperes (0-peak) 217.0 |

| HPK-B1611E | Peak Stall Current Amperes (0-peak) 338.4 |

| HPK-B1613E | Peak Stall Current Amperes (0-peak) 440.0 |

| HPK-B2010E | Peak Stall Current Amperes (0-peak) 312.0 |

| HPK-E1307C | Peak Stall Current Amperes (0-peak) 100.0 |

| HPK-E1310C | Peak Stall Current Amperes (0-peak) 142.0 |

| HPK-E1613C | Peak Stall Current Amperes (0-peak) 220.0 |

| HPK-E1815C | Peak Stall Current Amperes (0-peak) 312.0 |

| HPK-E1308E | Peak Stall Current Amperes (0-peak) 154.0 |

| HPK-E1609E | Peak Stall Current Amperes (0-peak) 253.0 |